AATOMOTIVE PAINT AND FINISHES

What a Detailer Should Know

PAINTS:

O.E.M.

The original finishes applied at the factory are chemically quite different from the products used in body shops for repairs. Because of the huge volume of vehicles they build each day and tougher air pollution regulations, the original equipment manufacturers use high speed finishing techniques and materials that release fewer solvents into the affnosphere. Some paint lines use automated reciprocating discs called turbo bells or mini-bells that rotate at up to 30,000 revolutions per minute. In order to

work properly in this high speed equipment, original equipment paints are thicker than refinishing products, with higher solids content. The same manufacturer will often use different suppliers of finishes at the same plant.

Over the years, car makers have used a wide variety of finishing systems on their vehicles, depending on the substrate involved and/or the plant capability. Some of these included:

o Conventional, lacquers -I2Vo solid solution lacquers

o Solution lacquers -I7Vo solid dispersion lacquers

o Conventional baked acrylic enamels -27Vo solid dispersion lacquers

o Melamine alkyd enamels -50Vo solids baked acrylic enamels

o Reflow acrylic lacquers

o Waterborne acrylic baking enamels

r Polyester basecoatlacryhcenamel clear-coats

o Acrylic enamel basecoat/clear-coat

o Urethaneenamelbasecoat/clear-coat

BASECOAT/CLBARCOAT

What is a basecoat/clear coat? It is the application of an unpigmented resin (clear coat) over a highly pigmented color coat (basecoat). Is it a clear coat or non -clear coat paint finish? Rub a small amount of gritted compound or polish into the finish. If the color of the paint transfers to the polishing cloth (pulls color), it is a non-clear coat finish. A clear coat finish will not transfer (pull) color.

Basecoat/clear coat (abbreviated BC/CC) technology was developed by O.E. Manufacturers to meet increasing demands of government environmental agencies, consumers, and O.E. Manufactures themselves.

Govenrment environmental agencies have become stricter on the release of solvents and other organic vapors into the atmosphere. Consequently, O.E. Manufactures have been required to formulate new coatings systems that emit lower amounts of organic

compounds. BC/CC is higher in application solids than the traditional non-aqueous dispersion lacquers.

Consumers have also been a significant factor in the improvement of O.E.M. coatings. With the increase in acid rain and other industrial pollutants, customers demand more durable systems. BC/CC has dramatically improved the chemical resistance of topcoats by

preventing the acid or alkali from penetrating the pigment. BC/CC coatings have also increased the gloss and DCI (depth of image), a never-changrng customer demand.

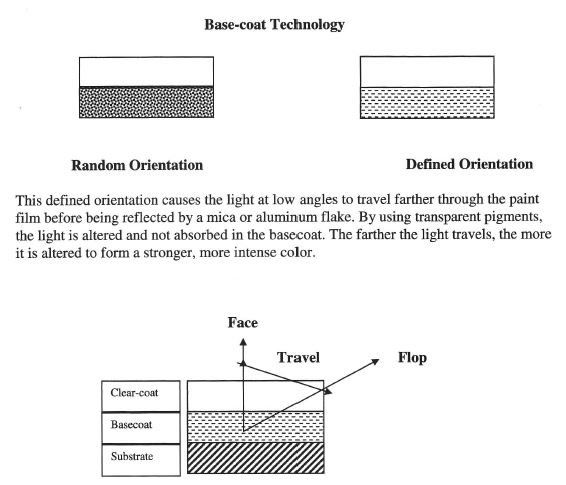

Finally, O.E. Manufacturers themselves have seen the styling advantage of BC/CC since manufacturers are constant$ competing for the attention of the consumer. Automotive color stylists use BC/CC s ability to use mica, aluminum, and transparent pigments to create an incandescent appearance that is appealing to consumers. These dramatic color effects are all made possible by the use of a basecoat resin technology that effectively controls the orientation of the mica or aluminum flake. This technology changes the normal random orientation to a more defined orientation.

The head-on color (face) is a lot less intense in color with more aluminum and/or mica flakes showing. The low angle color (flop) is a more intense, richer color with less aluminum and/or mica flakes showing through. This difference in color intensity between the face and the flop is sometimes called travel".

O.E.M. uses BC/CC technology to increase the brightness of an aluminum and or mica colors on the face, increasing the intensity on the flop. The clean, bright face and the rich flop increases the amount of travel, aluminum and or mica containing color, undergoes.

The increase in travel is the main reason color matching with non-basecoat and - conventional basecoat systems is more difficult. These systems can match the face or flop of a color, but they make it more difficult to achieve the "travel" of colors.